Recycled Plastic Driveway Grids

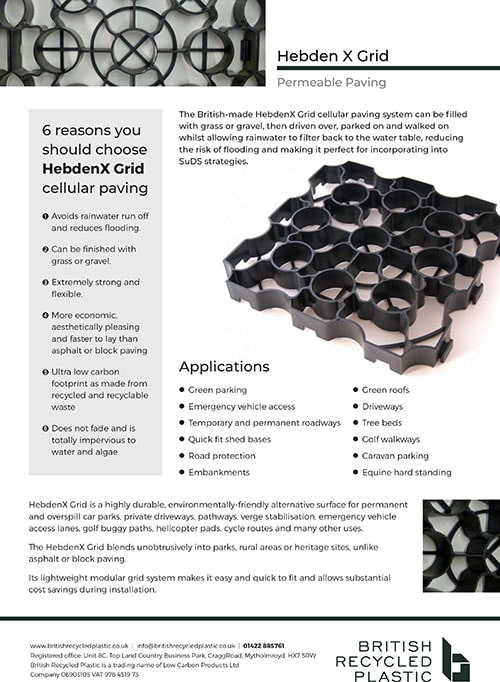

Driveway grids for both gravel and grass surfaces. Helps to prevent and alleviate surface pooling and flooding; approved SUDS (Sustainable Urban Drainage System).

Easy Eco Recycled Plastic Gravel Grids

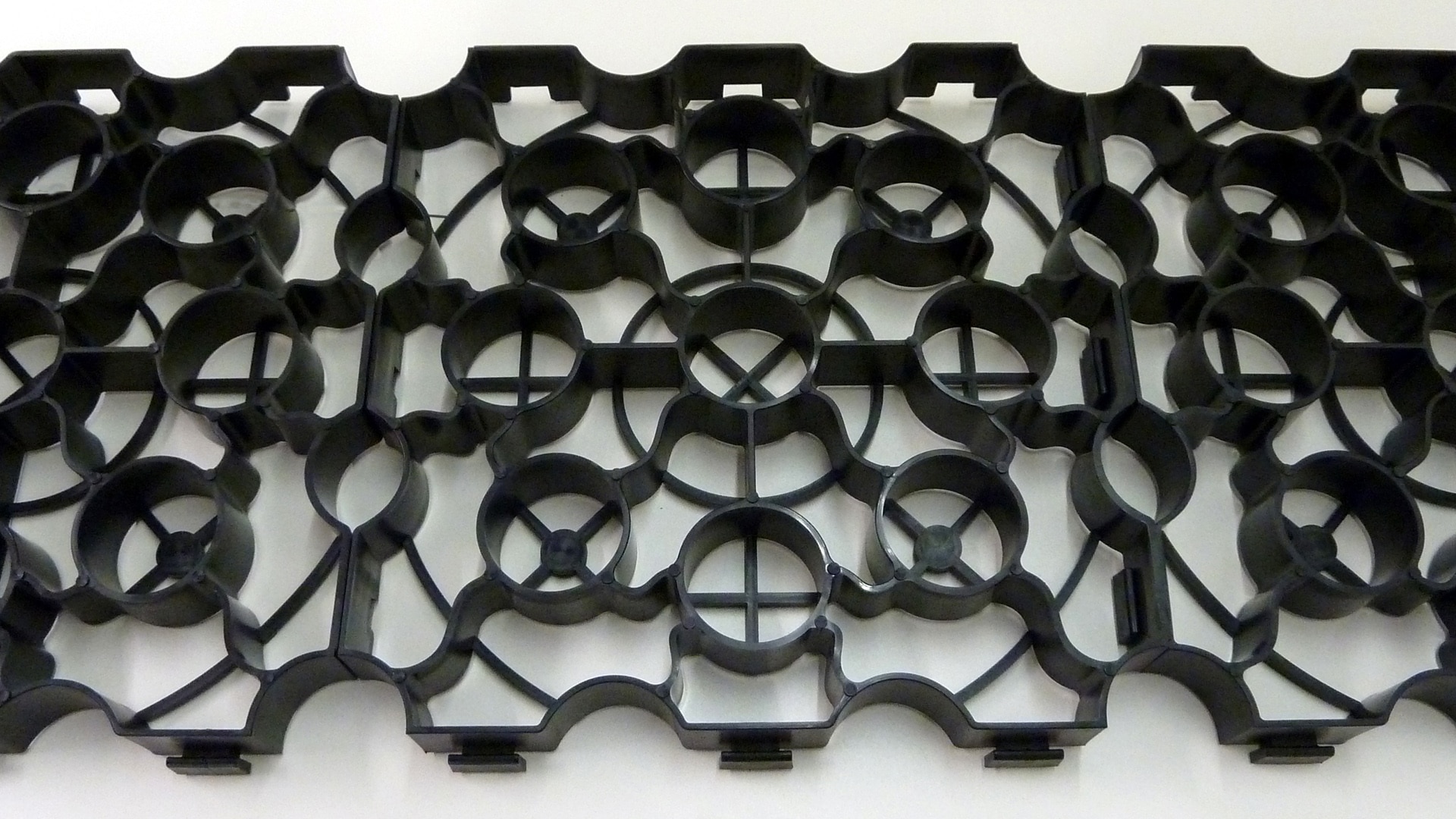

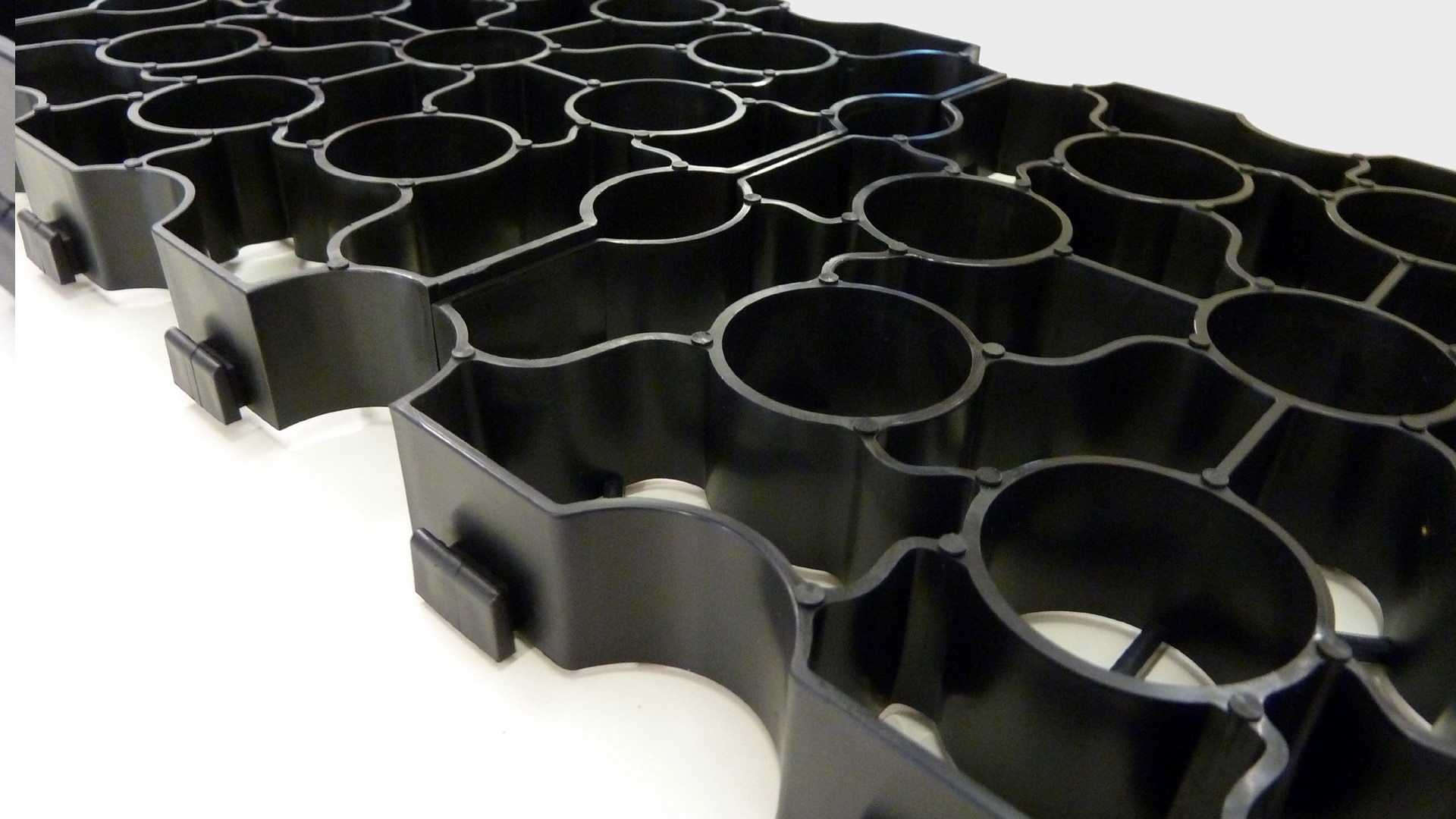

Made from 100% British recycled plastic, the Hebden X-Grid Recycled Plastic Driveway Grid provides a highly durable, permeable alternative surface for private driveways and pathways. SUDS-approved, no planning permission required for private properties.

How do they work?

Our driveway grids allow air gaps to form between pieces of gravel/soil. When the ground is saturated, these air gaps draw down surface water, holding it until the ground dries enough to allow it to seep back in. We call them driveway grids, but this type of product is often referred to as cellular paving, porous paving, ecopaving, permeable paving, ground reinforcement grids, SuDS pavers, gravel grids, ground stabilisation grids or plastic grid paving.

Grass or Gravel?

Our recycled plastic driveway grids can be finished with either grass or gravel, allowing them to blend unobtrusively and elegantly into private homes and rural areas whilst maintaining extraordinary load-bearing capabilities, unlike unsightly asphalt or expensive block paving.

For areas that get a lot of traffic, 14-20mm angular chippings are the most common filling for the driveway grids. This is because, not only do the chippings bed down to provide a stable surface, they are also big enough to avoid migration in the tread of the tyres of large vehicles.

You can fill your driveway grids with topsoil + grass seed for areas that see less traffic like private gardens and golf buggy routes as well as public car parking bays. The grass will need to be cut back once it has grown through the grids for the first time and then grow fully for a second time before traffic is allowed on to the grids.

For Pathways

If you have ever tried to push a wheelchair or a child’s pushchair across normal, unbound gravel you will know that it is such an incredibly hard thing to do therefore laying our recycled plastic driveway grids underneath the gravel will make it much easier.

If your path is in a public area, then you’ll be subject to Part M of the Building Regulations. This is the section of regulations which deals with ensuring access for all, regardless of any disability. Part M compliance requires the provision of a solid surface, suitable for wheelchair access. Our driveway grids hold gravel in place, allowing the stones to settle against each other and form a solid surface which won’t shift under narrow wheels. Of course, this makes our driveway grids a great choice for garden pathways, too – your wheelbarrow won’t get stuck.