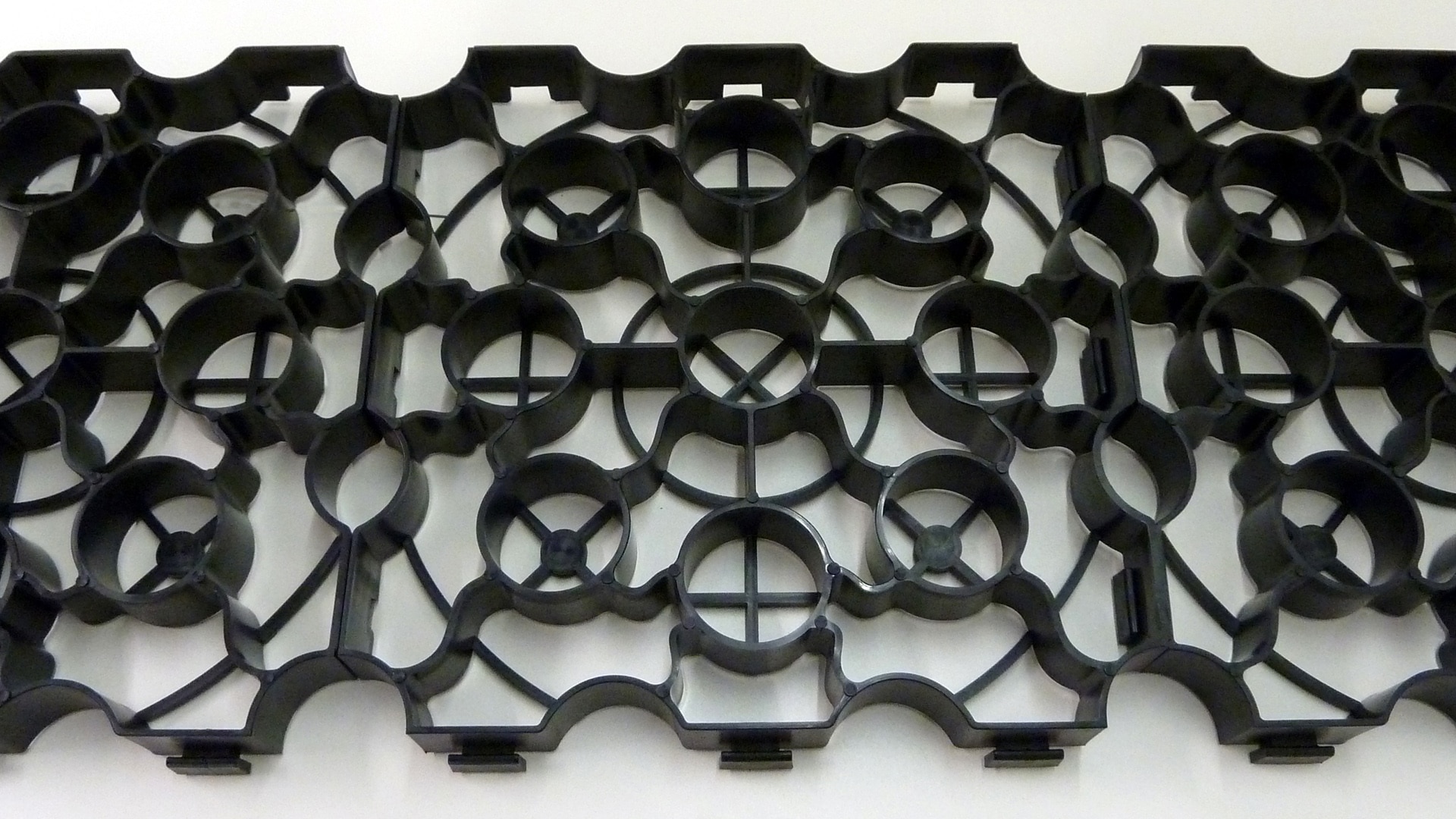

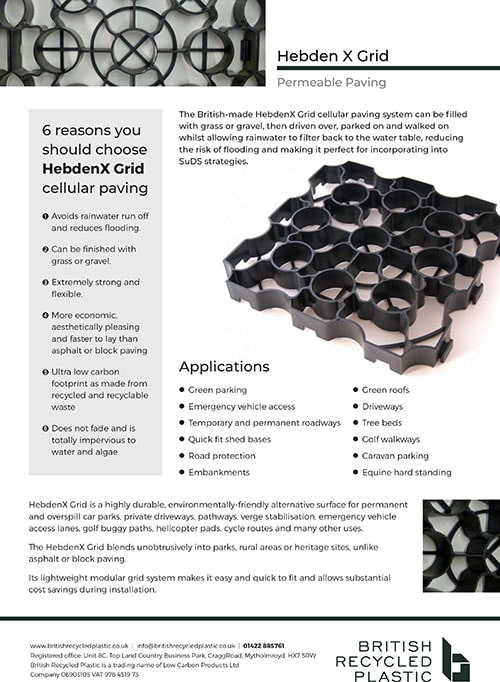

Recycled Plastic Ground Reinforcement Grids

Make car parks, access roads, laybys and pathways flood-resistant, firm, safe and more hard-wearing with Hebden X Grids ground reinforcement grids.

Recycled Plastic Grass Mesh Reinforcement

- Fill with gravel or topsoil + grass seed, for a turfed finish

- Low maintenance

- Wheelchair-friendly

- Weather resistant from -50C to 90C

- UV stable

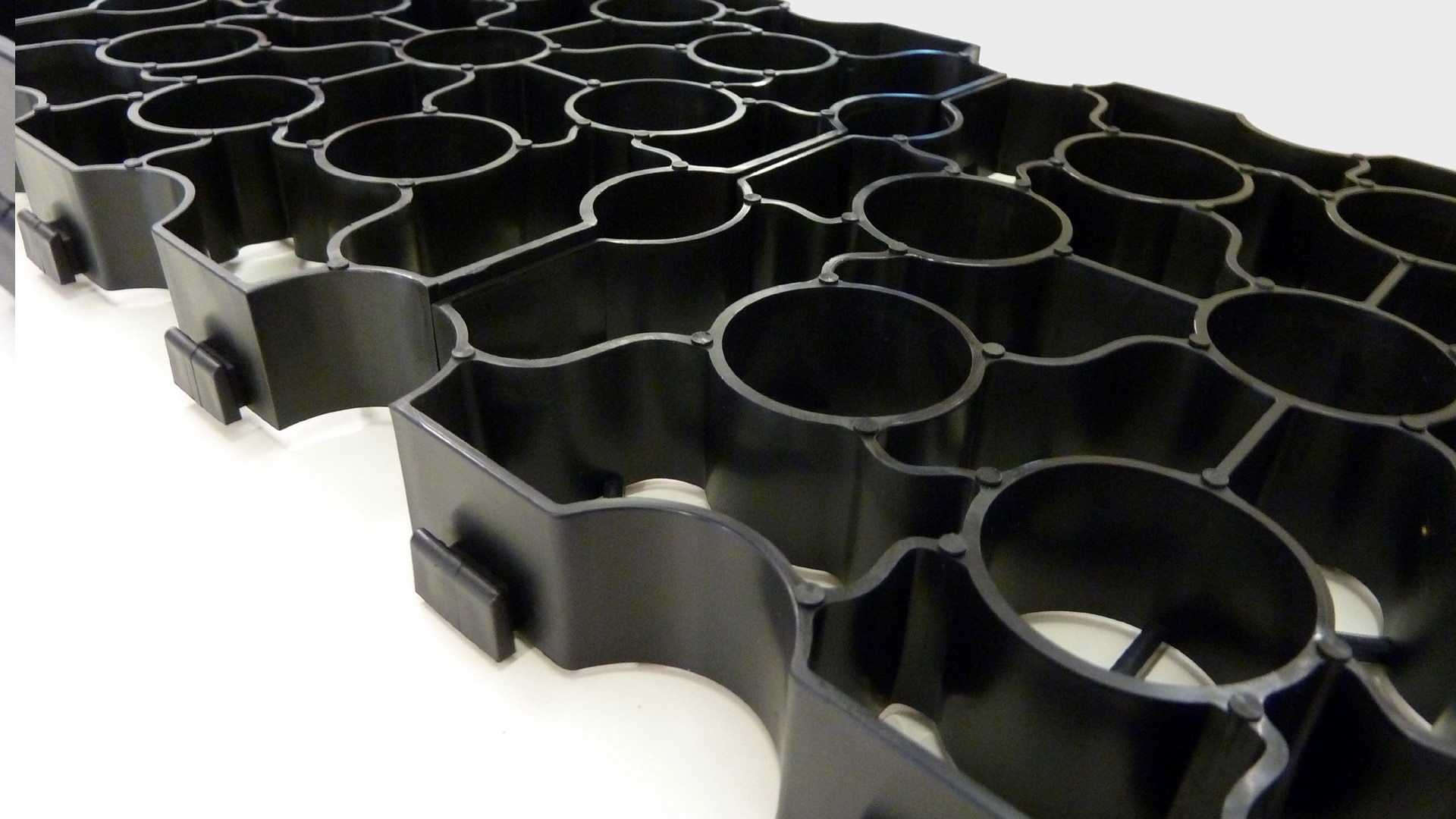

- Easy to install – lay 100m2 in one hour

- UK made

- 100% recycled and recyclable

Reinforcement Grids For Roads and Car Parks

Hebden X Grids will reinforce ground and provide a solid surface, able to take the weight of the majority of UK road-going vehicles. They’ve been used by National Highways (formerly Highways England) for laybys and service roads, as well as numerous private companies for access roads, pathways and car parks (delineators are available for marking spaces). With a loading capacity of 420 tonnes/m2, it’s DIN 1072-compliant, so meets regulations for use in roads and footbridges.

Rural Applications

Use wherever there is erosion or slippage of earth to firm and contain the ground, eliminating the need for annual backfilling. It’s a great choice for high-traffic gateways and paths prone to pitting and churning as well as preventing ‘desire lines’. It’s safe for equines, too.

Flood-Resistance and Alleviation

Wherever it’s used, it increases the capacity of that area to hold water, drawing excess down into its cellular structure and holding it until the ground beneath is able to reabsorb. It’s SUDS-compliant, so is appropriate for use in urban developments and doesn’t require planning permission for domestic driveways.

Wheelchair-Accessible

Hebden X Grids also prevent gravel from sinking around wheels, permitting inclusive access to users of a variety of mobility aids, including wheelchairs (both manual and electric). It’s part M-approved, so meets all the regulations – and is the surface of choice – for areas offering public access.

FAQ’s For Recycled Plastic Ground Stabilisation Grids

Vehicle Weight on Recycled Plastic Reinforcement Hebden X-Grids – With a maximum capacity of over 320 tons per square metre, almost any road-legal vehicle can drive over the Hebden ecopaving grids.

Notwithstanding, an appropriate substrate should be put down beneath the pavers, suitable to carry the weight of the type of vehicle that will be using it.

This should be the same depth as it would if tarmac or block paving was the final layer.

Ease of laying British Recycled Plastic Reinforcement Hebden X-Grids – Once the base or substrate has been laid, any reasonably healthy adult (or teenager for that matter) can lay the Hebden grids at a rate of around 100m2 per hour.

There isn’t any great need for skill.

Lay turf on top of Recycled Plastic Reinforcement Hebden X-Grids:

Unfortunately this is a common misconception, (although the hungry sales teams of some of our competitors try and lead their customers down this blind alley.)

Whilst it may be technically possible to use the Hebden grids like a “cake cutter” to slice through turf, it would require huge pressure, the like of which could only be applied by a heavy duty ground roller similar to those used by road laying teams.

We have tried to push it through, hit it with a mallet, and even drive over it, but the intermingling of the root network on any well grown slab of turf makes this all but impossible.

Another issue with adding turf in this way is the potential for voids, or pockets of air, between the bottom of the turf and the substrate below, ultimately killing the grass.

It’s best not do it.

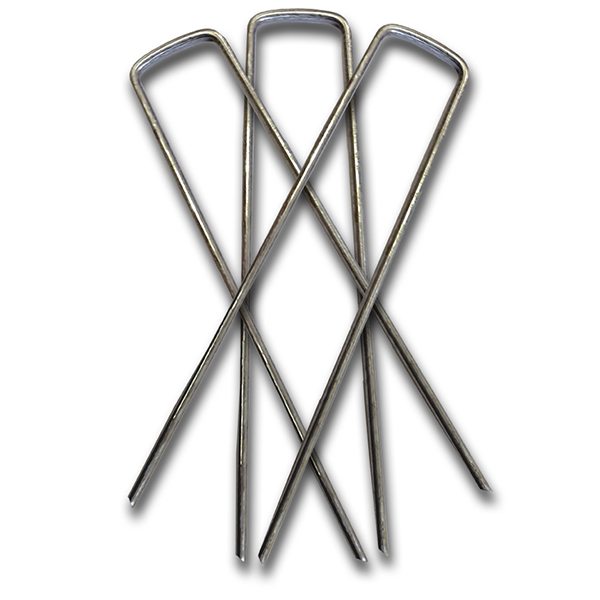

How to use Recycled Plastic Reinforcement Hebden X-Grids if they are laid on a slope of more than 1 in 20 it is advisable to pin the top edge at a rate of one stake per tile. If the slope is quite pronounced, you may wish to pin the sides too.

You do need to pin the Hebden grids down as stated above.

Gradient use for Recycled Plastic Reinforcement Hebden X-Grids can be used on gradients up to 1 in 10 if being driven over, although they will need pegging down at over 1 in 20.